Dear colleagues,

Have you noticed anything different about this issue? Globe is taking a new direction with a fresh layout, new sections, and more opportunities to get involved. Your feedback on the 2021 reader survey made it all possible.

Globe now features even more topics about the future, some of which are presented in our new Spotlight section. The strategic emphasis of this issue is “smart work, smart solutions.” Which intelligent solutions are we already using at GF? What are the opportunities and risks involved? And how “smart” will we be working in 2050? Read all about it here.

Of course the GF employees who continue to play a key role in Globe are also quite smart. For example, there is Chonggang Nie, our Hidden Hero, or Pramod and Suresh from India, who are helping a customer getting started in the Indian toy market. Christophe tells us how GF in Vällingby (Sweden) became our first climate-neutral site.

I am thrilled to share the new Globe with you.I hope you enjoy reading and exploring this issue!

Lena Koehnen

Globe Project Manager

Smart solutions for the future

Using intelligent solutions in an intelligent way – the feature story for this issue’s Spotlight explains how intelligent digital tools and artificial intelligence are used in every GF division.

How we will work in 2050

Futurist Ole Wintermann has been researching how we might be working in 2050. He reveals what will change in the coming decades and how we can adapt to it.

Artificial intelligence in the workplace: blessing or curse?

What are the pros and cons of artificial intelligence (AI) and digital tools in the workplace? Employees from different regions share their answers.

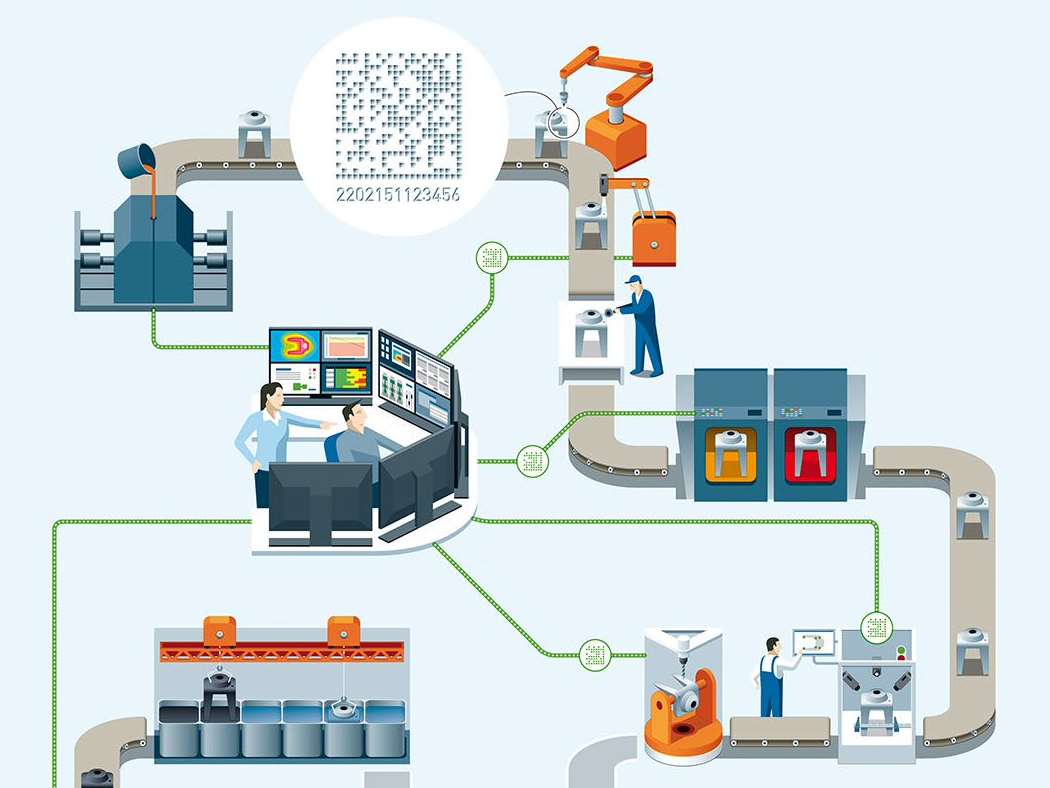

A special code for GF Casting Solutions

The data matrix code is revolutionizing the production of lightweight components at GF Casting Solutions. An infographic explains how this amazing code works.

Working smarter

This is what CEO Andreas Müller has to say about the current Spotlight topic "Smart Solutions."

A real team player

Chonggang Nie, a molding technician from GF Casting Solutions in Suzhou (China), ensures that new colleagues have a great start at GF.

Honest communication is the best way

Nathalie Isautier is Head of Human Resources at GF Machining Solutions in Biel (Switzerland). Find out how a negative experience early in her career shaped her personally.

Teamwork across borders

An international team from GF Piping Systems developed in record time a new production process for electrofusion couplers in India. Find out how they did it.

Climate pioneers

System 3R in Vällingby (Sweden) is the first GF site to become carbon neutral. Read here how the subsidiary of GF Machining Solutions achieved this and what other sites can learn from the site in Sweden.

Heading out to space with precision casting parts from GF

Precision casting parts from GF Casting Solutions head out into space every time an Ariane rocket is launched. Find out what is special about the components, and what role they play in space flight.

From wood waste to bioplastic

GF Piping Systems brought to market a climate-friendly alternative to hard plastics. Find out what the new material is made of and what advantages it offers.

© Eisenbibliothek

© EisenbibliothekCast from the same die

GF introduced stack casting in 1912. This was an important step in the serial production of fittings and other malleable cast iron components, as it saved time and space. Prior to casting, an employee would stack identical sand molds on top of one another. These were then pressed together mechanically. The molten metal was poured evenly into all the molds through a sprue, allowing multiple cast components to be produced in a single pour. The introduction of crane-operated ladles also reduced the risk of injury. The stack casting method was used until the 1950s.

Location: GF foundry, Schaffhausen (Switzerland)

Main product: Fittings

Temperature of cast iron: 1’150 °C (melting point)

Molds per stack: max. 8

New player on the Indian toy market

Sanco from India plans to conquer the toy market in India with sustainable products. GF Machining Solutions is supporting the company in the process.

A bit of GF in the morning

Find out here what GF Machining Solutions has to do with sparkling white teeth and being an important part of your morning routine.

A GF component for silver-screen secret agents

The magnesium beam produced by GF Casting Solutions was recently featured on the silver screen. Check out the most exciting facts about the component installed in the cockpit of the JLR Defender here.

Creating a winning culture together

The Culture Movement at GF aims to sustainably anchor the three new GF values and a winning culture in the company and among employees. You can find out more in the supplement to this issue of Globe.

Reader Feedback

Question

Dear Globe Team,

Globe magazine has developed nicely over the years and I always enjoy looking at it. However, since Globe is also available online, I think it is no longer appropriate in terms of sustainability to also offer a print version of the magazine. Is the paper edition still necessary? Regards,

Peter Barth, GF Piping Systems, Schaffhausen (Switzerland)

Answer

Dear Peter,

Thank you very much for sharing your view with us. We’re glad that you enjoy reading Globe. Your question is one that we have also been mulling over. After publishing two online-only issues, we discovered that we cannot reach the majority of our employees worldwide with an online-only format. The Globe reader survey also showed that the majority of our readers prefer the magazine in print. We will therefore continue for the time being to offer a print version of Globe. However, based on feedback from our locations, we are continuously optimizing the circulation. By the way, Globe is printed on FSG-certified recycled paper. And starting with this issue, we are also supporting a tree project to offset some of the CO2 produced during printing.

Regards, your Globe editorial team

What about you?

Do you have feedback for Globe or would you like to ask the Globe editorial team a question? Then send an e-mail to globe@georgfischer.com